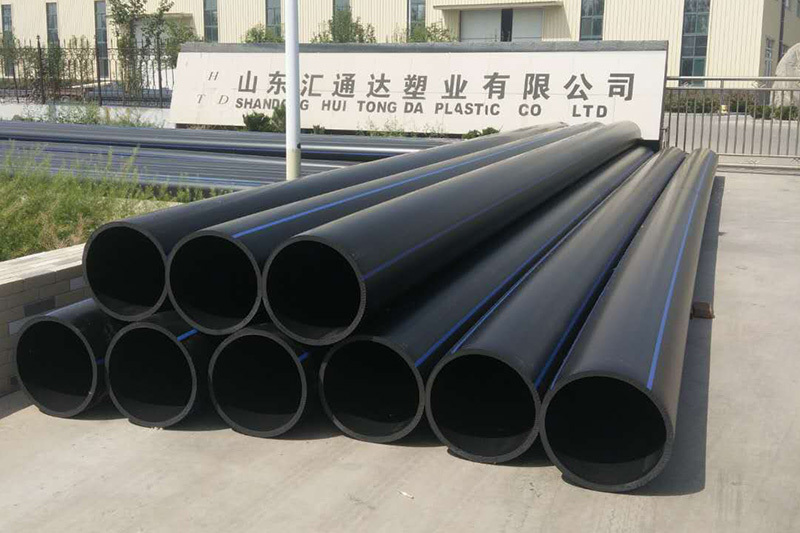

HDPE Pipe

Keywords:

Classification:

Product Introduction

1. Good hygiene performance

Polyethylene (PE) pipe and pipe fittings material non-toxic, is a green building materials, ISO standard grading polyethylene materials for 0 (the lowest grade) no mildew material, compared with other commonly used plastic materials, polyethylene mold resistance performance is much higher, do not breed bacteria, no secondary pollution; Corrosion resistance, long - term use without scaling. In line with GB/T17219-1998 safety evaluation regulations, can effectively improve the water quality of pipe network.

2. Greater circulation capacity

The inner wall of polyethylene (PE) pipe and fittings is smooth and does not change with the use time. The friction resistance is small and the pressure loss is about 30% less than that of steel pipe, which can effectively reduce the energy consumption of water supply and increase the circulation capacity by more than 30% compared with other general pipes.

3. Good impact resistance

Polyethylene (PE) pipe and fittings have good flexibility, high impact strength and strong earthquake resistance. Its elongation at break is more than 400%. It has strong adaptability to uneven settlement of pipe base, and it is a kind of pipe with excellent seismic performance.

4. Good anti-cracking performance

Polyethylene (PE) pipe and fittings have good resistance to rapid crack transmission. Excellent scratch resistance and outstanding environmental stress cracking resistance.

5. Long service life

Polyethylene (PE) pipes and fittings have a minimum safe service life of 50 years under normal conditions.

6. Easy to recycle

Polyethylene (PE) materials can be recycled, even incineration treatment will not produce substances that have environmental impact.

7. Good construction performance

Polyethylene (PE) pipe and fittings are light in weight, simple in welding process, convenient in construction and low in comprehensive cost.

Product Message

Related Products

East Fourth Ring Road, Yucheng High-tech Zone, Shandong Province

Focus on Huitongda